Overview

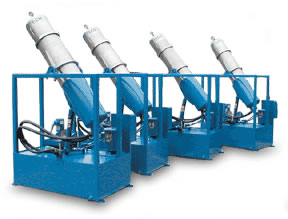

Stacked disc depth filters provide superb filtration for the most demanding filtration applications.

Polytech designed filter systems utilizing this filtration technology as an alternative to diatomaceous earth precoat filter systems which are historically used in these applications.

Filtration well under one micron is available in a simple, low cost package that avoids the complexity of precoat and backflushable extended life media systems and the mess of manual precoat filters. Our stacked disc depth filters also eliminate workplace concerns about airborne silica.

Applications

- Carbide Grinding

- Abrasive Slicing

- Honing, Lapping, & Superfinishing

- Vibratory Finishing

- Glass & Ceramics

- Diamond & CBN Abrasive Machining

- Wire EDM

- Sinker EDM

How it Works

Our filters use a technologically advanced gradient density depth filter media of fully bonded cellulose fiber and diatomaceous earth.

The fibers are laid down so that the openings decrease in size from the entry to exit surface capturing ever finer particles as the liquid passes through the media. The crystaline structure of the diatomeceous earth provides a high void volume for dirt holding capacity.

Specifications

Stacked disc depth filters are suitable for synthetic water based coolants and straight oils. The droplet size in emulsions of soluble oil is big enough to be stripped out by the filter media.

Design and Customization

Stacked disc depth filters can be combined with other filtration and separation techniques to reduce operation cost and increase filter life.

A common combination filter in honing and superfinishing is a first stage magnetic separator followed by a stacked disc filter housing.

These filters also find application in coolant or oil polishing on a side loop for removing small fines (such as carbon from cast iron finishing) that would build up to an intolerable level otherwise. Removing this build up extends the life of the coolant or oil.

Speak to one of our engineers about your application's specific requirements.